The 20th edition of the fair is very close. It returns to an in-person format to showcase innovative products and technologies that have been rewarded by two years of steady market growth. Also taking center-stage will be the latest Sacmi Deep Digital solutions and high-efficiency, energy-saving kilns and dryers. Even more eye-catching, enhanced ceramic products thanks to Sacmi Deep Digital solutions and highly efficient, versatile, energy-saving forming and firing technologies. Qualities like these have made Sacmi the industry’s leading technology provider. And, at the Revestir fair in São Paulo, Brazil (8-11 March 2022), the company will soon be showcasing innovations that have already gained the widespread approval of a strategic market that has grown steadily since 2020.

Taking center-stage at the fair will be ceramic slabs and tiles decorated with Sacmi Deep Digital technology, products with wide-ranging floor, wall and furnishing applications. One of the most outstanding developments in this field is the Sacmi DDG (digital decoration & glazing) solution, the only machine on the market capable of performing two digital, synchronized, dry and wet applications to create finishes with unparalleled texturing and depth.

Positive market feedback has taken the form of several projects recently completed by leading Brazilian players who see DDG as crucial. Already, in just the first few months of this year, they’ve used DDG to develop and release new high-added-value product lines.

Whether the topic is digital decoration or firing, Brazil, like any other country, has to deal with the sweeping changes affecting international markets. These have two main components: a growing need to reduce consumption and emissions in line with standards and sustainability goals, and an even more pressing need to contain costs in the face of surging gas prices. The Sacmi FMA range of kilns offers a perfect response to both: on the cutting-edge Maestro series they feature high-efficiency burners, modulated and partitioned air-gas feeds plus the option of installing kiln-kiln and kiln-dryer or kiln-spray dryer energy recovery solutions. There’s also plenty of scope for revamping existing systems thanks to new consumption optimization kits for fixed-air kilns that can cut average consumption by up to 8%.

Participants at Revestir can also take a virtual tour of the Sacmi Lab, which partners with customers all over the world to create innovative products and provide specialist training and on-site assistance. Some of the slabs displayed at the fair were made and decorated at the Lab itself; these reflect the growing demand for high-end products such as digitally decorated spray-dried body porcelain tiles; as the main Brazilian players adjust their production plans accordingly, lines for such products will soon join the more traditional wet porcelain and dry red body tile manufacturing operations.

This Sacmi-driven revolution runs parallel with new forming machines, from high-tonnage presses to Continua+ solutions; the latter have continued to evolve in recent years and now provide not just higher productivity but even greater flexibility when it comes to managing production mixes. Last but not least, they have automation and control: customers can opt for HERE, the plant supervisor designed by Sacmi to meet ceramic manufacturers’ specific needs.

This 2022 edition of Revestir, then, gives Sacmi a golden opportunity to build relationships with Brazilian customers in person. Moreover, the event runs parallel with the growing dynamism of a market that has, for the first time in years, seen output exceed 1 billion m2. And supporting that market is Sacmi do Brasil, which has supplied over 70 locally-built complete kiln and dryer lines for Brazilian customers and boasts a 70-strong production, sales and assistance team.

Without forgetting the sanitaryware solutions that make Sacmi the world’s leading partner; tehy’re taking the industry towards ever-greater automation and digitalization by providing everything from Sacmi RobotGlaze systems to high-performance kilns, plus full automation of the process via RobotCasting (pressure casting). Sacmi also leads the way in the tableware industry, once again thanks to a global network of companies, unrivalled know-how and a sharp focus on new projects recently developed by Brazilian customers.

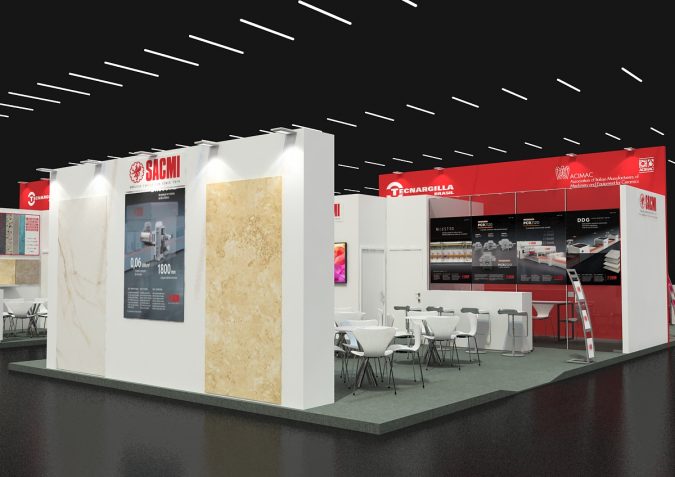

Sacmi, a green & aesthetic tile manufacturing r-evolution. Join them at stand n. 2051A from 8 to 11 March.